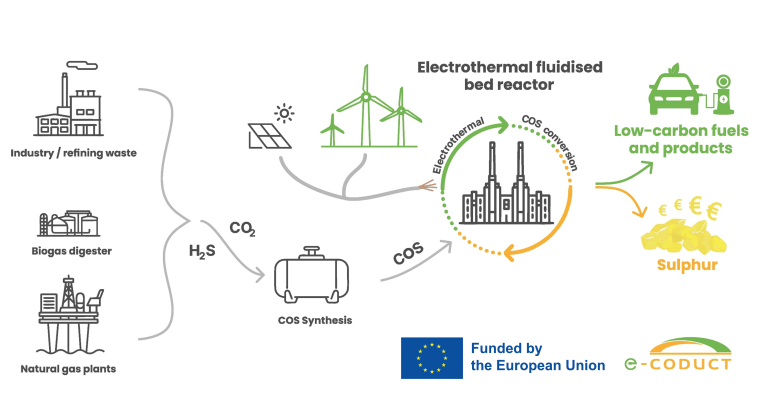

The e-CODUCT project is developing a pilot plant to demonstrate the conversion of common industrial waste streams, CO₂ and H₂S, into value-added products, using renewable power. This technology aligns with the European Green Deal and will improve environmental performance in various industrial sectors. The technology’s ability to efficiently process mixed gas streams and its integration potential into current industrial processes emphasize its economic and environmental benefits, which have been confirmed by a comprehensive techno-economic assessment and life cycle analysis.

The CO2 emissions should be decreased thanks to the specificity of the reactions. This will be a first-of-a-kind electrified process for CO2 conversion into platform molecules with demonstrated techno-economic, environmental feasibility and scalability studies.

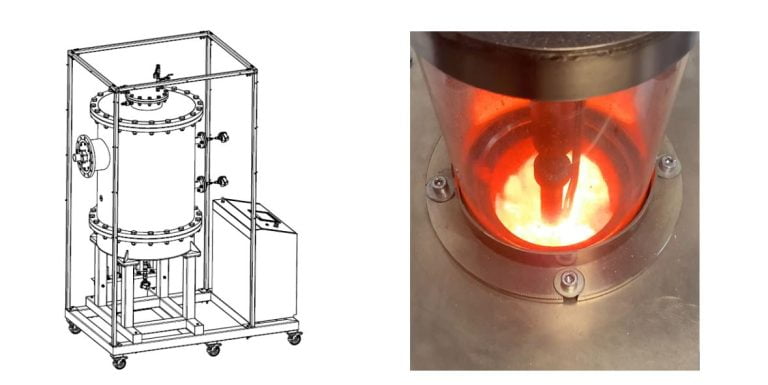

The consortium has finalised the reactor design and demonstrated the feasibility of the electrothermal fluidised bed (ETFB) reactor prototype. Challenges in construction, raised by highly corrosive atmosphere and high operating temperatures (>1000 °C), have been successfully overcome by selecting special high-performance materials for ETFB reactor manufacturing. To progress on the integrated pilot, a first version of P&ID has been consolidated. Then, a preliminary HAZOP has been performed. A mass and energy balance sheet of core e-CODUCT technology, with a black box diagram model, TEA and LCA models and an industrial planning tool are under development.

Catalytic tests have demonstrated the conversion of acid gas (H2S and CO2 mixture) into COS under mild conditions, leading to the selection of high performing catalysts able to generate a pure stream of products. The catalysts are shaped into extrudates with optimized formulation to be used in industrial reactors. Then, COS is decomposed to CO and S using newly developed ETFB reactor technology. CO is furthermore valorised continuously into platform molecules, such as methanol (CH3OH) in a high-pressure fixed-bed catalytic reactor, while S is directly recovered as marketable product.

The e-CODUCT project team has took part in several events that provide perfect opportunities to engage with our cutting-edge research and innovative solutions and to network with leading experts in the field.

[SEP 2023] YUCOMAT – Materials Research Society of Serbia, Montenegro

TOPIC: e-CODUCT: Electrified COS decomposition and subsequent methanol synthesis

[OCT 2023] FEARS – UGent Faculty of Engineering and Architecture Research Symposium, Belguim

TOPIC: Industrial planning of electrically heated catalytic reactors with an intermittent power supply

[MAR 2024] GFZ 2024 – Groupe Français de Zéolithes Annual Meeting, France

[APR 2024] NGCS13 – 13th Natural Gas Conversion Symposium, China

TOPIC: Electric catalysis: from renewable energy to valorized gas

[MAY 2024] GECat 2024 – Congress of Groupe d’Etude en Catalyse, France

[JUN 2024] ACHEMA 2024 – World Forum for the Process Industries, Germany

TOPIC: e-CODUCT: Fast-Response electrically heated catalytic reactor technology for CO2 reDUCTion

[JUL 2024] ICC Lyon 2024 – 18th Internationa l Congress on Catalysis, France

[2] COS thermal decomposition as a step of e- CODUCT technology – simultaneous reduction of H2S and CO2

[3] Electricity is in the catalyst: a reaction engineering approach to gas treatment and valorization